LT BMS is a Battery Management System (BMS) based on Linear Technology's (LT's) LTC6804 Multicell Battery Monitor Chips and the Arduino Uno (or Linduino One) microcontroller board. It provides an API to control and read data from '6804 chip chains.

This repository includes:

- Two C++ classes for controlling stacks of addressed LTC6804-2 chips or DC9143C demonstration boards connected on a multidrop isoSPI bus. These include functionality to write configuration registers, read battery cell voltages and status registers, and control General-Purpose Input-Output pins on each chip (e.g. to interface thermistors).

- Several Arduino sketches that demonstrate the functionality of the LTC6804 and DC9143C classes.

- An Ardiono sketch that controls a Manzanita Micro PFC charger based on cell voltage readings from DC9143C demonstration boards.

- Download the Arduino IDE.

- Download or clone this repository onto your machine:

$ git clone https://github.com/whileman133/lt_bms.git

- Either change the Arduino Sketchbook location to the cloned repository (

lt_bmsdirectory) or add the folders underlibrariesto your Arduino libraries folder.

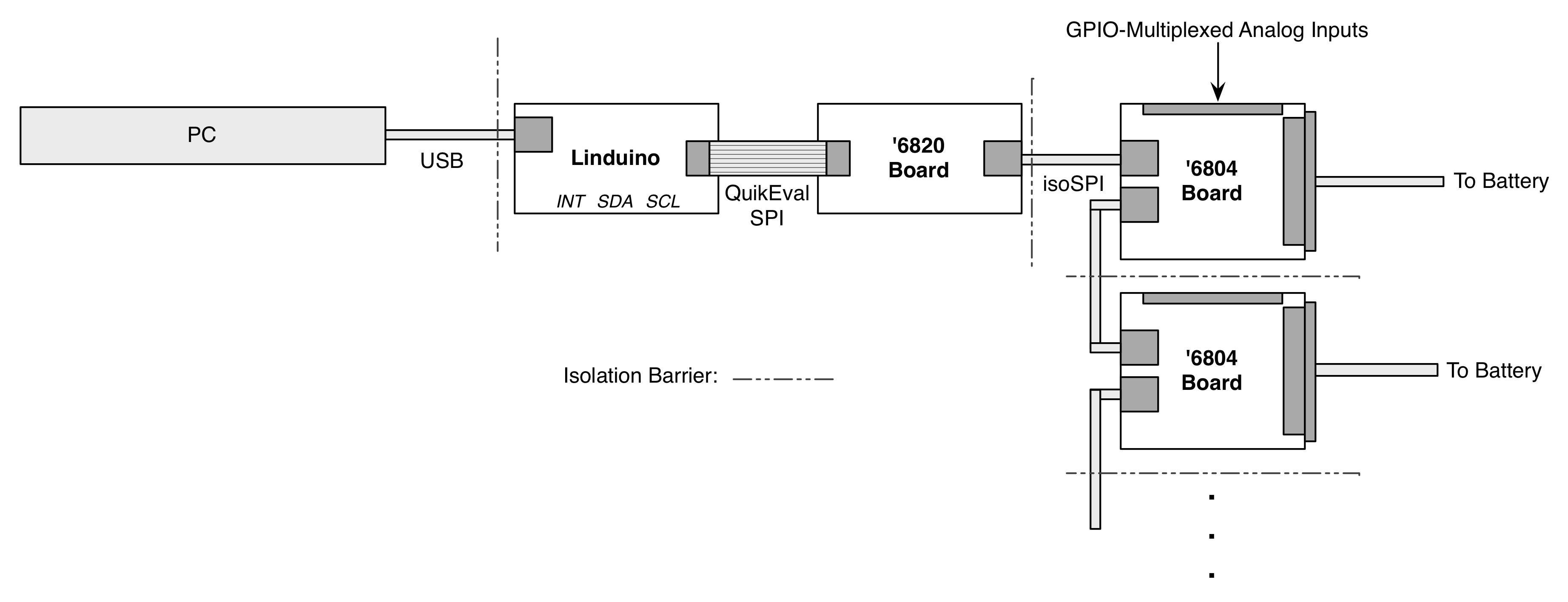

The interface consists of two C++ classes: LTC6804_2_Stack for functionality pertaining to stacks of bare LTC6802-2 battery management chips and DC1942C_Stack, a subclass of LTC6804_2_Stack adding functionality to read the multiplexed analog inputs on DC1942C demonstration boards. Figure 1 shows a typical configuration of a LTC6804 chip stack.

Figure 1: LTC6804 stack diagram

The LTC6804_2_Stack class leverages the Timer/Counter1 of the ATmega48 microcontroller contained on the Linduino board to keep the LTC6804 chip's watchdog timers from expiring and reseting their configuration bytes.

Most of the API's digital-architecture dependent functionality (i.e. the LTC6804-2 chip's memory map) can be altered by changing program-memory lookup tables rather than the code itself.

To use the interface, place the folders in the libraries directory of this project in your Arduino libraries directory. Then create a sketch and construct one or more DC1942C_Stack objects (the API will control more than one stack at a time if needed):

#include <DC1942C_Stack.h>

#include <Linduino.h>

DC1942C_Stack stack( CHIPSELECT_1 );

DC1942C_Stack stack2( CHIPSELECT_2 );

//...The pin to use as the SPI chip select pin for LTC6802 SPI-to-isoSPI board interfacing the Arduino with the stack is the only parameter to the constructor.

After constructing the stack objects, call the setup method on each to initialize the chip-select pins. Finally, call the static DC1942C_Stack::start() method to enable SPI communications the watchdog reset timer:

void setup() {

stack.setup();

stack2.setup();

// ...

DC1942C_Stack::start();

}To write configuration words to the chips, you'll need to declare an array to hold the configuration group:

uint16_t configData[LTC6804_NUM_CONFIG_WORDS] = { 0 };It's recommended you place this declaration in your sketch's global scope so you can periodically read back the chips' configuration words and validate them against the correct words. Make sure to initialize the words array to zero to ensure proper functionality. (Note the LTC6804_NUM_CONFIG_WORDS define is included in the DC1942C_Stack library.)

Then use the prepare_config method to generate the desired configuration words for each stack:

void setup() {

//...

stack.prepare_config(

configData,

PD_NONE, // GPIO pulldown enable

REF_ON, // REFON bit

ADC_OPT_1, // ADCOPT bit

// Use included macros to generate codes corresponding to under- and over-voltage values

UV_THRESHOLD_CODE(2.0), // Undervoltage threshold

OV_THRESHOLD_CODE(3.6), // Overvoltage threshold

D_NONE, // Cell discharge shunt enable

DISCHARGE_TIMEOUT_OFF // Cell discharge timer

);

}Write the prepared comfiguration to all of the chips in a stack via the following:

#define NUM_ICS 6

// addresses of the ICs in the stack

const uint8_t IC_ADDRESSES[NUM_ICS] = { 0, 1, 3, 4, 6, 7 };

// ...

void setup() {

// ...

stack.config_all( NUM_ICS, IC_ADDRESSES, configData )

}Use the start_cell_voltage_adc, adc_delay, and verify_all_config methods to read cell-voltages in either fixed-point or floating-point format.

The thermistor_read_all method can be used to read temperature data when thermistors are connected to the multiplexed inputs.

See the DC9142C_test sketch for more useage details.

See the DC1942C_control sketch.