The goal of this project is to be a flexible API for generating ortholinear-ish (column-staggered) keyboards, and particularly split, concave keyboards often called Dactyls. You can start with my preferred keyboard and modify it to your needs, or use the API to build your own 'from scratch' without the pain of re-writing the details you don't care about.

This project starts with the assumption that one-size does not fit all, and so a keyboard user will want to tune their dactyl to achieve the greatest comfort possible. In this process, a number of design-print-test iterations will be required and while the process of 3D printing can be a significant time delay, beyond a certain point its not possible to spend extra time designing and avoid the need to print and test. Given this, it makes sense to optimize the modeling software for faster iteration time at both the design and print level, and to expose both easy configuration for bootstrapping and more fine-grained control for tuning. This way you can Try All (the) Dactyls!

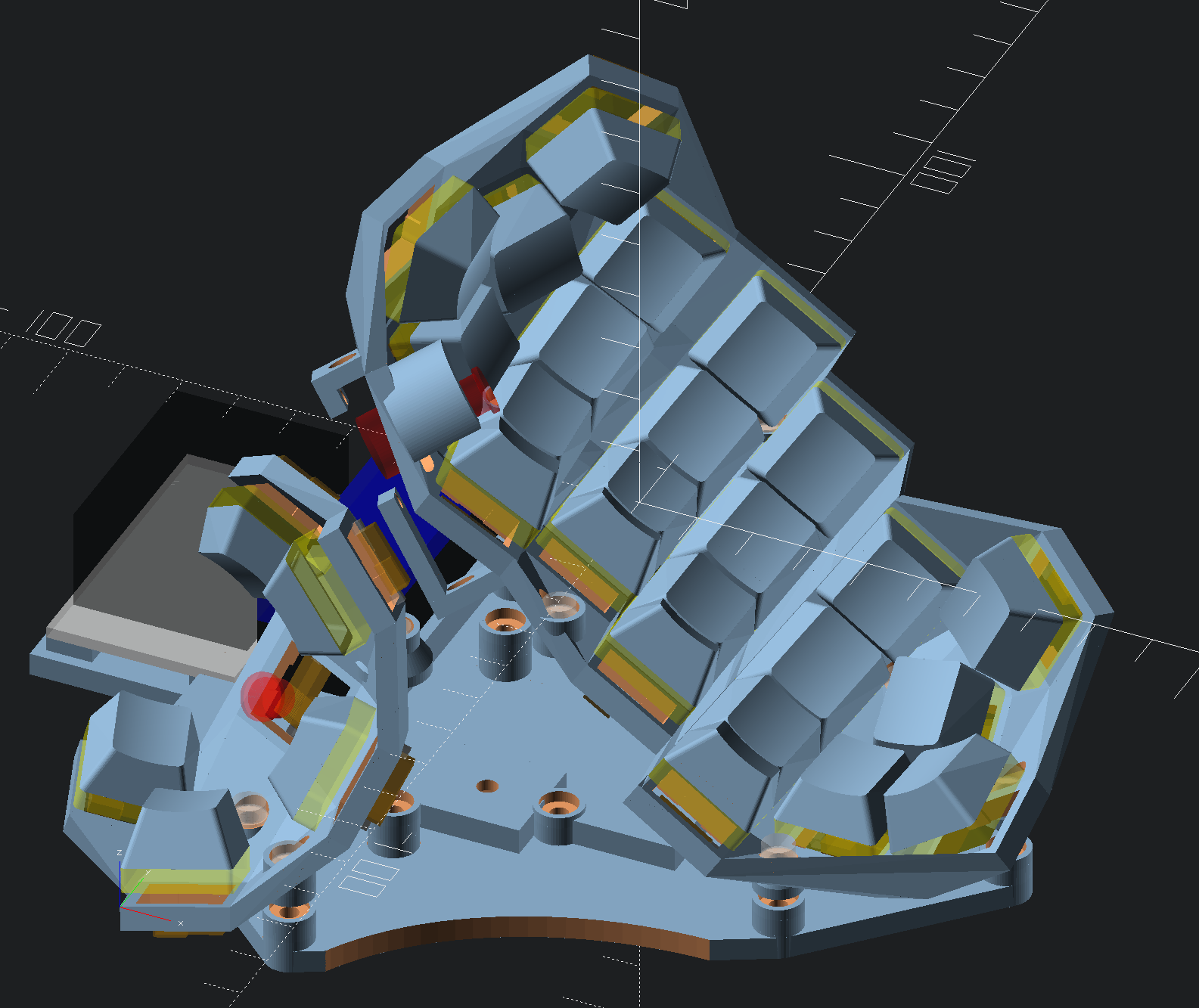

- faster previews - writing in pure OpenSCAD lets us see changes as fast as possible, rather than using a generator-style binding with a more traditional programming language that must be executed (and possibly compiled) before changes will be visible

- faster prints - support for multiple case styles allows quicker turn around with more open models like the Dactyl Manuform Skeleton Edition-inspired case, and then the ability to print the same layout with a more protected case with sidewalls when you've settled on a design

- placement in terms of the keycap tops, not the key switch holders - control where you want your fingers to be, not where the switches go; this means you can keep the same exact layout and change from e.g. Cherry profile to DSA (provided the keycaps don't collide)

- all parameters correspond to measurable quantities - combined with the above, makes it easier to say things like "I want to move the equals key 2 mm closer to my pinkie" and get the results you want

- library / API style approach - gives you the tools to build what you want, and makes it easy to plug in different keyswitch / keycap styles without having to rewrite half the code

- no post-processing needed - it should be easier to incorporate unanticipated additions directly in OpenSCAD than to take an .stl and munge it somewhere else

I also aim to document an easy approach to handwiring that both simplifies the initial process and allows easy reuse of the electronics as you switch from case to case. You can find a brief summary here.

- uses sculpted Cherry keycaps as though they are a flat profile

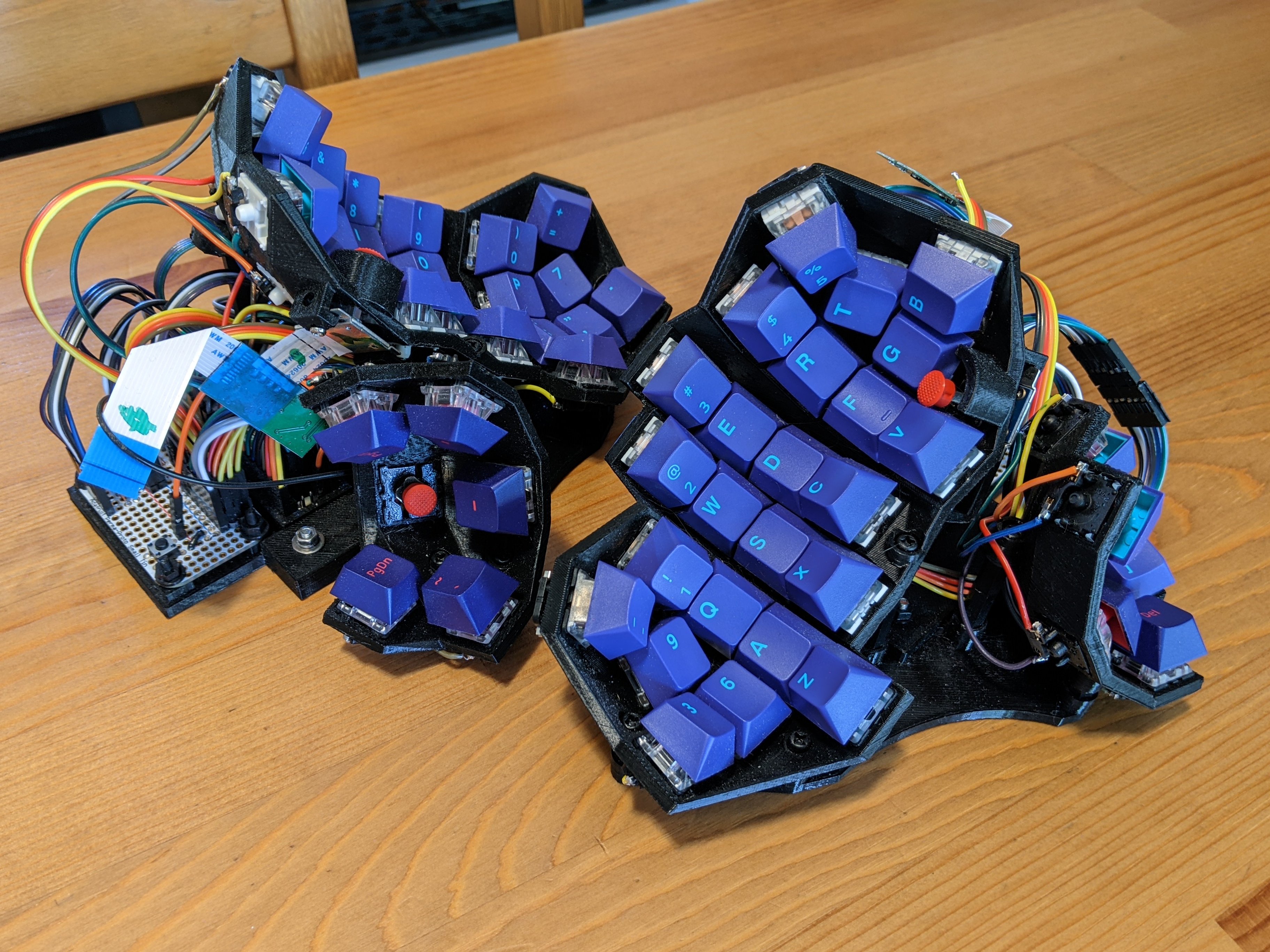

- concave, spherical thumb cluster, with a 5-way nav switch

- Trackpoint!

- spherical "pair" of columns under pinkie and index, with lowest key in the outside column moved to the homerow, one column further out

- on the index, this makes room for the trackpoint without cutting keycaps

- on the pinkie this makes for a more comfortable extension of the finger to the side to press shift, rather than curling up and pressing down and out

- recessed magnets in the base plate, to hold the keyboard firmly to an adjustable metal tray. I documented my approach for mounting peripherals to my chair arms here.

- orthogonal row/column placement styles including flat and cylindrical (cylindrical row + cylindrical column == spherical placement of thumb keys, for example)

- pluggable support for new placement styles (spirals anyone?)

- ability to automatically place things (like trackpoints, screws, and support struts) at the corners between keys so they don't collide with switches and keycaps, even when using complex placements

- pluggable keycap support (add a new profile with a single function)

- pluggable switch support

- per-key configuration overrides

- stick a Row 1 key next to a Row 4 key seamlessly by changing keycap profile row

- Favorite keycaps don't come with an ortho/ergo kit? Use 'traditional' wide modifier keys with you non-row staggered design by setting a position offset.

- multiple case styles, automatically generated base plates, and easy manual tuning of strut or wall placement

- visual indications in preview-mode for identifying keycap collisions (including key travel, when pressed) or hotswap socket collisions with the model or each other

These are abbreviated descriptions of what lives where. See the linked files for detailed documentation comments.

-

Keys - the most basic building blocks of a keyboard (you are unlikely to need these directly)

- key/mount.scad - The

key_mount()is the basic switch holder. there are also various bounding boxes around the sides of the keywell used to stitch keywells together into a switch plate, and to generate sidewalls for a case when desired. - key/cap.scad - The

keycap()model manages caching of pre-rendered .stls when possible and by default hides the caps when rendering a keyboard for printing.position_flat()orients akeycap(), orkey_mount()with the origin at the center of the top of the keycap.effective_rows()produces the data structure used to map row/column indexes to keycap profile rows used by a given layout, such as a keyboard without number row that uses only R2, R3, R4.

- key/mount.scad - The

-

Columns - the main unit of organization for our designs, one or more columns per finger

- column/layout.scad -

layout_columns(rows, cols, homerow, homecol, ..., keys, wells, walls, ..., params)is the main module exposed to the user for creating a keyboard. It creates a connected plate ofcolskey columns withrowsrows. Thehomerowandhomecolgive the coordinates of the key that is centered on the origin. This is mostly important for curved placements. The booleankeyscan be used to disable display of keycaps in previews,wellscontrols generation of the switch plate, andwallscontrols the creation of walls, which are independent of the switch plate. The booleansleftwall,rightwall,topwallandbottomwallcontrol a separate way to generate simple, regular walls that are reasonable for flat keyboards with a shallow tent and tilt. Awall_matrixmay be specified instead to give per-key control of the wall sides and distance (including multiple articulation points). The params struct is generated by the function below. - column/util.scad - The function

layout_placement_params()produces a pseudo-struct containing all the user supplied configuration parameters, for convenience.layout_placement()is the low level module all the higher level APIs use to uniformly place child modules at row, column coordinates, using the placement_params. The functionscreate_flat_placement()andcreate_circular_placement()create structs passed tolayout_placement_params()for row or column alignment. The flat placement take an [x, y] pair (or vector of pairs, or vector of vector of pairs) specifying distance in millimeters. The circular placement takes a [chord, radius, angle] triplet (or vectors thereof) specifying the relationship between two points on a circle, using any two of: the the shortest-line distance between the points (a chord), the radius of the circle, or the angle between the two points from the center of the circle.normalize_chord()calculates the missing parameter from the other two, but should be automatically called anywhere a chord is accepted to sanitize the input. If a single value is provided to these functions, the spacing between successive rows or columns will be uniform. If a vector of values are provided, the distance used for each successive row or column relative to the previous can be tweaked. using a vector of vectors allows it to vary both per-row and per-column. missing rows, or columns, will be substituted with the last specified value. Theoptional_vector_index()automates this lookup-with-substitution process.optional_index()is the version used for scalars, likerows.

- column/layout.scad -

-

Accessories

- assembly/rest.scad -

wrist_rest_base()is the model for @crystalhand's holder for a silicone palmrest. this file invokes it and adds mounting dimples for rubber feet and a flush mount for a bar-shaped cup magnet. (TODO add @kennykaye style rest) - assembly/trackpoint.scad -

install_trackpoint(row, col, ... displacement, params, ... use_shield ...)places a mount for a trackpoint so that the stem rises through the intersection between keys nearer to thehomerowandhomecolof the key specified byrowandcol.displacementcan be used to tweak this positioning without having to modify theparamsused for the rest of the switch plate.h1andh2can be used to move the arms of the trackpoint mount so they contact the switch plate and don't collide with the switches.use_shieldenables a cylindrical covering to protect the trackpoint stem extension, if the trackpoint is not fully encircled by keys. - util.scad - utilities for hulling sets of modules while preserving their concavities; utilities for mounting magnets, rubber feet, microcontrollers, and other electronics.

- assembly/rest.scad -

-

Keyboards

- settings.scad - controls various parameters mostly pertaining to key caps, switches, spacing and rendering settings

- assembly/util.scad - the

screw_mounting()module and associatedscrew_mounting_params()function for adding screw-attached support struts between switch plate and base plate - assembly.scad - my personal skeleton-edition style keyboard

- debug-new-walls.scad - my closed-case keyboard experimentation

To view the keyboard assembled, run openscad assembly.scad. This is how I normally make edits. Within assembly.scad the base plate is generated in debug mode which just shows the strut mount placement, so that strut heights can be manually adjusted, and so that renders are faster. To see the full keyboard, find the line base_plate(debug=true); and change to false.

For printing, the assembly/fingers.scad, assembly/plate.scad and assembly/thumb.scad models can be used to obtain separate parts. trying to print the whole assembly as is would be unlikely to succeed. I like to use the commandline to invoke openscad for renders, like the following: openscad -q --hardwarnings --render -o things/plate.stl assembly/plate.scad.

To validate that changes to the library code have not introduced regressions, run make test prior to editing (or after a git stash), which will generate reference .stls for later comparison. Run make test again after editing to see if the tests still produce identical .stls. New tests should be added when new positioning functions, keycap profiles, or other features are introduced. The tester models should also be useful to those who might like to print a smaller model to consider the feel of a given column shape without wasting time and material printing a full keyboard.

Right now testing is a bit fiddly. Edit testers/wrapper.py to point SCAD_EXE at a nightly build of openscad, which has the sort-stl feature. Even with that, .stl files aren't always consistent. The alternative approach also has issues. Blog post incoming :)

Why not just use a flat keycap profile and save yourself a lot of work?

-

Using a flat profile doesn't actually solve the problem. For example, when you do cylindrical placement of the switch holders, rather than the keycap top surfaces, the radius does not correspond to measurements of the fingers and their movement. The radius is longer because the height of the switch and keycap can be a sizable percentage of the finger length. Rather than calculating this offset manually, it makes sense for the software to make the compensation for you.

-

I'm not aware of a cylindrical topped (rather than spherical) flat MX profile, which I prefer.

-

Sculpted profiles tend to have angled sides, and top surfaces that are noticeably smaller than a full 1u footprint, which lets you pack them a bit more tightly if you aren't looking for a full 19.05 mm spacing between keys. This also seems particularly important for the spherical key placement i use, because its more at risk of keycap collisions than cylindrical. However, I haven't yet investigated the spherical placement with a flat profile, so maybe it's less of a concern than it seems.

-

Many colorways are limited to specific (sculpted) profiles. I started this project after being completely blown away by the GMK Copper renders, for example.

-

Flexibility: my design can accommodate flat profiles. It may even give the most pleasing results that way. It can also accommodate sculpted profiles. It could even be used to add a sculpted effect to a flat profile (or change the sculpt of a sculpted profile). To each their own, as they say.

-

Cherry profile R3 has a lower vertical height that DSA or XDA. Obviously chocs are a superior choice for low profile switches, but I don't like linear switches and I love my Kailh Speed Copper switches, so Cherry profile helps me shave off some height.

- key (profile & switch/well) configuration architecture

- add and test SA profile support

- add and test DSA profile support

- parameterize switch (choc, void, ???)

- use this to support SKRH and RKJXS nav switches instead of profile row?

- expand

mxstem()to incorporate switch type - how to generalize

innerdia,outerdiaandthickness - separate keywell use of

spacer()from assembly.scad level use- think about automatic decisions about using minimum keywell dimension vs being wide enough to prevent hull from colliding with 1U keycap vs wide keycap support vs being as wide as whatever the keyspacing is to maybe avoid hulling if adjacent key is the same profile and has identical positioning (tent/tilt/offset etc.)

- test traditional modifier key support

- add concept of key width or is using offset good enough?

- columns

- document layout_columns arguments

- spiral placement

- figure out how to connect 2 rectangles (faces of a keywell) in 3D space without hull (functional OpenSCAD seems like a good bet, or BOSL2?)

- alternatively use the corner sphere bounding boxes for everything to guarantee thickness and accept the cost (and figure out how to avoid colliding with keycap)

- case

- finish closed case

- join the walls of each finger's switch plate

- consider bridging over some keys on the sides

- generate closed case base plate

- add cylindrical perimeter to skeleton-edition case

- support raised perimeter bezel

- more wall code cleanup

- hack up and test a @kennykaye-esque palmrest? use JellyTitan magnetic feet?

- finish closed case

- general

- reorganize code into directories?

- re-locate util functions

- rename

keywell()to ???switch_holder()??? to reflect that keywell is generally accepted to mean concavity - decide how multiple case style support and rendering of individual parts can be generalized