This repository contains the implementation of a facings identifier using YOLOv8 and image embeddings. The goal of this project is to count the number of facings (product instances) of each product present on shelves in a retail store using computer vision techniques.

Accurate and efficient inventory management is crucial in the retail industry for optimizing operations and improving the customer experience. One significant challenge faced by retailers is accurately counting the number of product facings—the individual instances of products displayed on store shelves.

Manual counting of product facings can be time-consuming and error-prone, especially in large retail environments. To address this challenge, computer vision techniques offer an automated solution. By leveraging algorithms and models, retailers can analyze shelf images to detect and count product facings accurately.

The facings identifier using YOLOv8 and image embeddings presented in this project is an example of utilizing computer vision techniques. By combining YOLOv8, an advanced object detection algorithm, with image embeddings that capture essential visual features, the system can automatically detect and count product facings with precision. This approach improves inventory management efficiency, provides insights into product availability and products shelf share of space.

In summary, automating the counting of product facings through computer vision offers retailers valuable benefits by monitoring the facings on their shelves.

YOLO is a popular real-time object detection algorithm that performs object detection directly on the entire image in a single pass, providing faster results compared to other methods. YOLOv81, developed by Ultralytics, is the latest version of this algorithm, leveraging advancements in deep learning and computer vision to offer superior speed and accuracy. It can be easily adapted to different hardware platforms and is suitable for various applications.

Image embeddings are compact numerical representations that capture the unique characteristics of an image. They are generated using advanced deep learning models trained on large image datasets. These representations encode high-level information about the content of an image, enabling computers to understand and compare images effectively.

By using image embeddings, we can measure the similarity between images, perform image search, and organize images into meaningful categories. In the facings identifier project, image embeddings help identify the brand of each product facing by comparing the embeddings of different product images.

In summary, image embeddings are powerful tools in computer vision that allow us to represent and analyze images in a way that computers can understand, enabling various applications in image recognition, search, and organization.

In this project, image embeddings are utilized to identify the product name of each identified facing.

The methodology for the facings identifier using YOLOv8 and image embeddings involves two steps:

- identifying SKUs from a shelf image

- predicting the brand for each detected SKU.

In the first step, a YOLOv8 model is trained using the SKU110K dataset to detect SKUs in shelf images. This model can predict bounding boxes and labels for each SKU, providing valuable information for inventory management.

The second step focuses on predicting the product of each detected facing. This is done by leveraging image embeddings, which are numerical representations capturing essential image features. The embeddings are generated using pre-trained deep learning models and compared to identify product clusters.

By associating clusters with product names in a knowledge base, the model can predict the product of a new facing image based on similarity to known clusters. This enables accurate counting of facings and facilitates inventory management in retail stores.

In summary, the methodology combines YOLOv8 for SKU detection and image embeddings for brand prediction, enabling efficient and accurate counting of facings using computer vision techniques.

For this step, a model was trained using the YOLOv8m (medium) model and the SKU110K dataset2. Due to hardware constraints, the training was performed using a Kaggle notebook. The notebook and the model weights are available here.

To identify SKUs in an image, the following code snippet demonstrates the usage of the trained model:

from ultralytics import YOLO

model = YOLO('best.pt') # weights loading

model.predict(

source="data/img/retail.jpg",

save=True,

save_crop=True,

conf=0.5,

project="data",

name="knowledge_base",

)During the detection process, image crops for each detected SKU are saved using the save_crop parameter, which will be used in the second step.

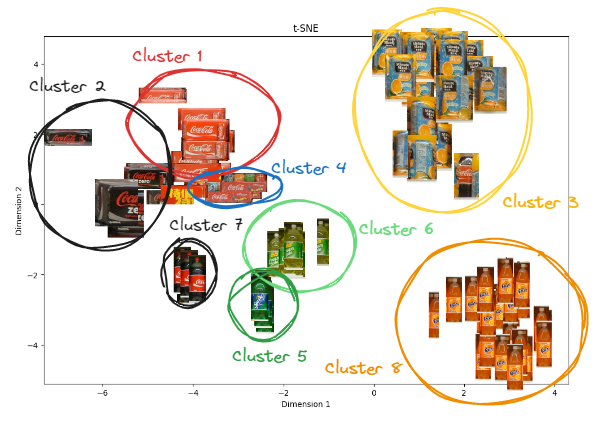

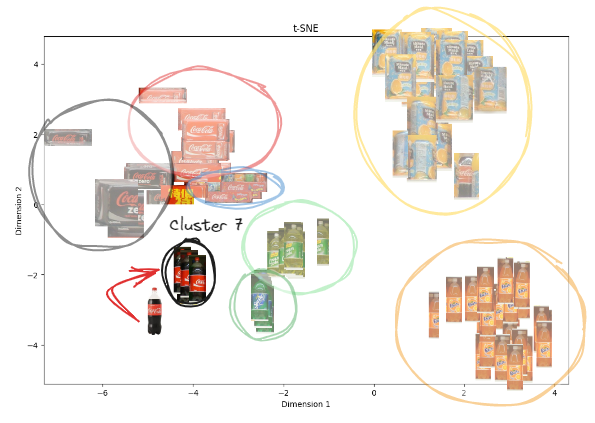

To predict the product for each facing crop, an embedding model is applied to identify different product clusters using cosine similarity. The t-SNE3 technique, a statistical method for visualizing high-dimensional data, helps to visualize this process. In the t-SNE embeddings representation, similar product crops are grouped together.

When a new unknown crop is added, it is placed close to the most similar product crop based on the embeddings. This allows us to assume that the unknown product is the same as the closest crops.

In this notebook you can find an implementation of the T-SNE

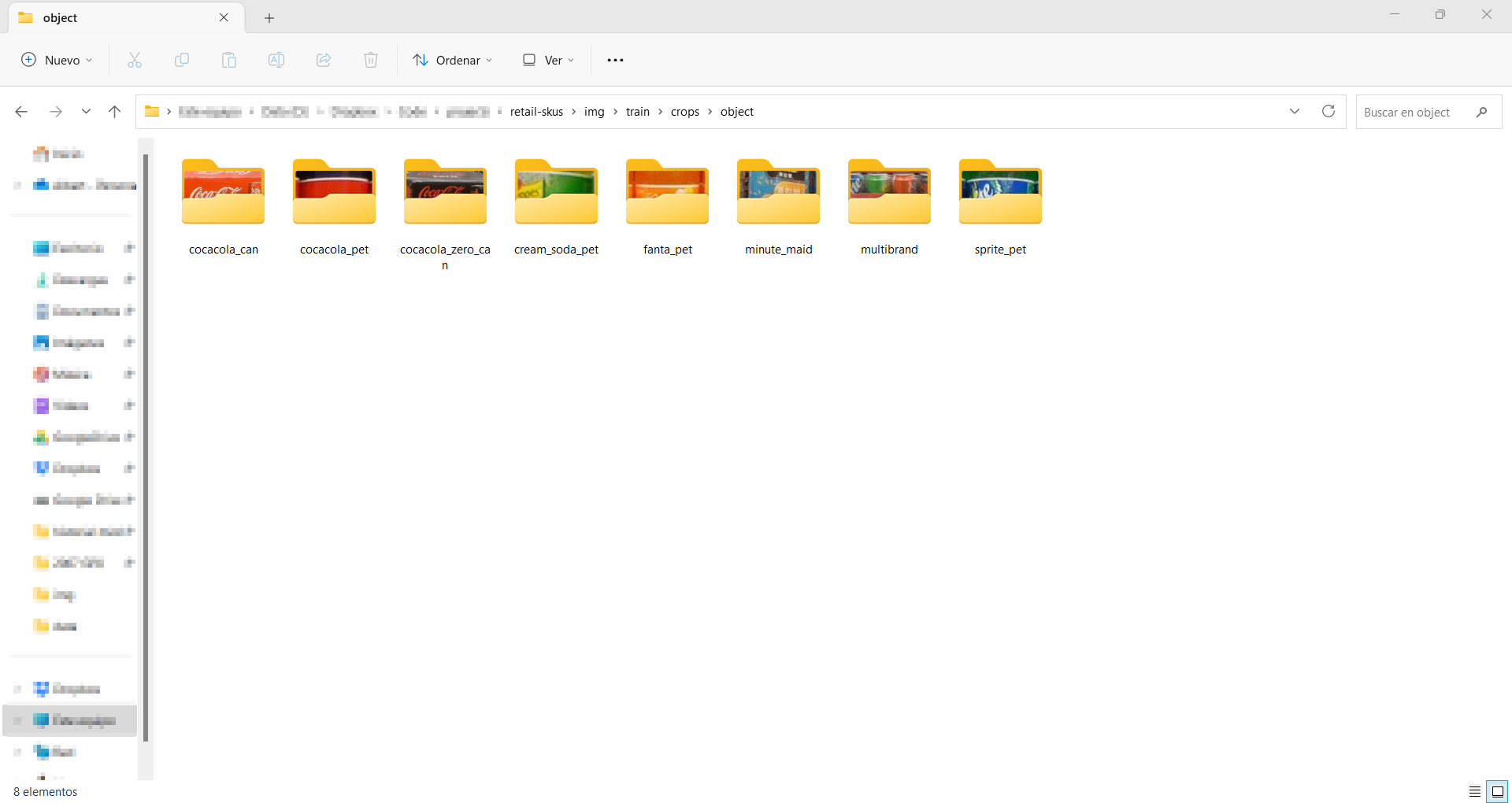

However, the model does not know the names of each cluster. Hence, manual work is required to classify the crops into folders with corresponding descriptions. This step is equivalent to renaming all the clusters, such as "Cluster 1" becoming "Coca-Cola can" and "Cluster 2" becoming "Coca-Cola Zero can," and so on.

This knowledge base is used for further predictions and impacts the predictions in two aspects:

- The predictions are limited to the products that have been classified.

- The predictions are more accurate with a larger number of crops available for comparison.

To predict the product of a new facing image, refer to this notebook where all these techniques are implemented

To evaluate the performance of the model, we conducted testing using an image captured in a supermarket. It is important to note that the knowledge base used for this test includes only a specific set of products. Therefore, the model's performance is expected to be accurate only for those particular products.

Despite the image not being captured at the optimal angle, the model demonstrates its capability to correctly identify most of the product facings.

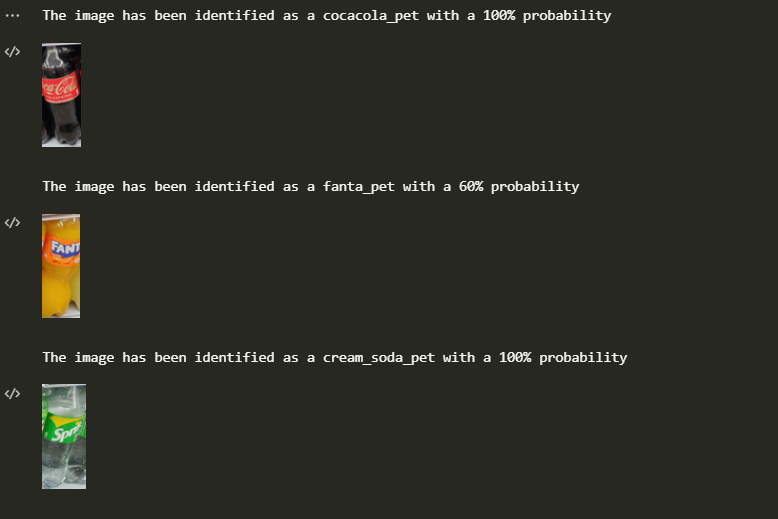

In this specific test, the crops analyzed included Coca-Cola PET (Crop 26), Fanta (Crop 77), and Sprite (Crop 48). The model successfully classified two out of the three products correctly based on the knowledge base that was created:

However, the model misclassified the Sprite PET as Cream Soda. This discrepancy can be attributed to the difference in logos between the Sprite product in the image and the Sprite representation in the knowledge base. This example highlights the significance of maintaining a comprehensive and regularly updated knowledge base.

Assuming you have Conda installed on your system, follow these steps to set up the environment:

Creating the environment

conda env create -f env.yamlActivating the environment

conda activate facings-identifierReinstalling pytorch

pip install --force-reinstall torch torchvision torchaudio --index-url https://download.pytorch.org/whl/cu118Identifiyng crops from a shelf image

Assuming the image you want to analyze is located at data/img/testing.jpg, you can use the following command to identify the different product facings and predict their corresponding product names:

python main.py --input "data/img/testing.jpg"The script will utilize the pre-trained model and the knowledge base of classified crops stored in data/knowledge_base to make predictions. The results will be saved in a text file located at data/testing/predictions.txt. The file will have the following format:

the crop image testing is predicted as cocacola_can with a 100% probability

the crop image testing10 is predicted as sprite_pet with a 80% probability

the crop image testing11 is predicted as cocacola_pet with a 80% probabilityIn conclusion, this project demonstrates the possibility of developing software capable of extracting crucial data from images in the retail industry. By leveraging computer vision techniques, we can automate the process of counting product facings on store shelves, leading to improved inventory management and operational efficiency.

Moving forward, there are several potential next steps to enhance the system:

- Improve the Knowledge Base: Maintaining an extensive and up-to-date knowledge base is crucial for accurate predictions. Continuously expanding the knowledge base with new product information and classifications will enhance the model's performance and allow for better identification of product facings

- Train a Larger Model: Consider training a larger model with an increased number of epochs. Investing in training a model can significantly enhance the system's accuracy and deliver more reliable results.

- Store Predictions in a Database: To leverage the extracted data effectively, consider storing the predictions in a database. This will enable further analysis, trend identification, and data-driven decision making.

- Build a Monitoring Dashboard: Develop a monitoring dashboard that visualizes the extracted data and provides real-time insights. This dashboard can include metrics such as count product facings, out-of-stock occurrences, and share of space.

By pursuing these next steps, retailers can fully leverage the potential of computer vision and image analysis to revolutionize inventory management processes. The automation of product facing identification, coupled with data-driven insights, empowers retailers to make informed decisions, streamline operations.

This notebook has been a helpful resource for understanding and implementing similar image recommendation systems.