- The AML Robot Cutting Dataset consists of approximately 1500 seconds of real data collected on Kinova Jaco 2 robot retrofitted with a custom end-effector fixture and dremel performing cutting tasks on wood specimens for 5 materials and 5 thicknesses.

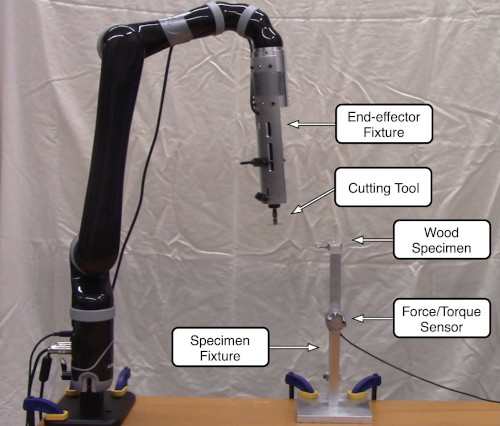

- The test bed consists of the following components:

- Kinova Jaco 2 Arm: A light-weight six-DOF robotic manipulator with a maximum payload of 2.6 kg without the original gripper. The robot is equipped with joint encoders and joint torque sensors. During the data collection, the robot was controlled manually through Cartesian velocity control via a joy stick controller.

- Cutting Tool and End-effector Fixture: Designed as a replacement for the original three-finger gripper of the robot, the end-effector fixture is responsible for holding the cutting tool. The cutting tool, equipped with a wood cutting circular saw blade, is a Dremel 100 Single Speed Rotary Tool.

- Specimen Fixture: This component provides a firm support for holding the wood specimens and measuring the cutting force using an integrated force/torque sensor in the middle of the fixture.

- Force/Torque Sensor:: We have used an ATI Mini40 as the force/torque sensor. The following table shows the sensor properties:

| F_x, F_y | F_z | T_x, T_y | T_z | |

|---|---|---|---|---|

| Sensing Ranges | 20 N | 60 N | 1 N.m | 1 N.m |

| Resolution | 1/200 N | 1/100 N | 1/8000 N.m | 1/8000 N.m |

- The cutting test bed is set up as the picture below:

If you are using this dataset in your work, please cite the following paper. It will be published in IROS 2020.

@article{rezaei2020learning,

title={Learning the Latent Space of Robot Dynamics for Cutting Interaction Inference},

author={Rezaei-Shoshtari, Sahand and Meger, David and Sharf, Inna},

journal={arXiv preprint arXiv:2007.11167},

year={2020}

}

- The dataset has been collected on 12 unique wood specimens each being cut 15 times, thus resulting in a total of 180 cuts. The rods have been selected from sets of five materials and five thicknesses, but due to the limitations in the selections, not every size was available for each material. The following table presents the details of the cutting dataset:

| Cut No. | Material | Thickness (in) | Datapoints |

|---|---|---|---|

| 1 | LVL | 3/16 | 980 |

| 2 | LVL | 1/4 | 923 |

| 3 | LVL | 5/16 | 937 |

| 4 | LVL | 3/8 | 1721 |

| 5 | LVL | 7/16 | 1865 |

| 6 | Maple | 1/4 | 1206 |

| 7 | Oak | 1/4 | 1070 |

| 8 | Birch | 1/4 | 1033 |

| 9 | Maple | 3/8 | 1420 |

| 10 | Oak | 3/8 | 1369 |

| 11 | Birch | 3/8 | 1228 |

| 12 | Hardwood | 3/8 | 1111 |

| Total | 14863 |

-

The dataset consists of three directories:

-

robot_data: Robot states and some other useful information collected in the form of bagfiles.ROS topics list in each bag file: /j2n6s300_driver/in/cartesian_velocity 100 Hz : kinova_msgs/PoseVelocity /j2n6s300_driver/out/actual_joint_torques 10 Hz : kinova_msgs/JointAngles /j2n6s300_driver/out/cartesian_command 10 Hz : kinova_msgs/KinovaPose /j2n6s300_driver/out/compensated_joint_torques 10 Hz : kinova_msgs/JointAngles /j2n6s300_driver/out/joint_angles 10 Hz : kinova_msgs/JointAngles /j2n6s300_driver/out/joint_command 10 Hz : kinova_msgs/JointAngles /j2n6s300_driver/out/joint_state 10 Hz : sensor_msgs/JointState /j2n6s300_driver/out/tool_pose 10 Hz : geometry_msgs/PoseStamped /j2n6s300_driver/out/tool_wrench 10 Hz : geometry_msgs/WrenchStamped -

ft_sensor_data: Force/Torque sensor data measuring the cutting force and torque at 200 Hz. -

data: Processed robot data (see Instructions for more information).

-

-

The two data streams were not synchronized at the time of collection and a post-processing step is required for their synchronization.

-

Note: The synchronization is a work in progress.

- Python 2.7+

- Rosbag

- Matplotlib

- Numpy

- Pandas

The process_data.py script loads the bagfiles and reorganizes them in CSV files while adding the

corresponding labels. The CSV files are easier to handle in PyTorch and TensorFlow. To generate them,

run the following command:

# From aml_robot_cutting_dataset/aml_robot_cutting

python2 process_data.py

This creates the data folder in the root directory, containing all the CSV files for each cut.

Use the argument --save_plots to save the corresponding plots.