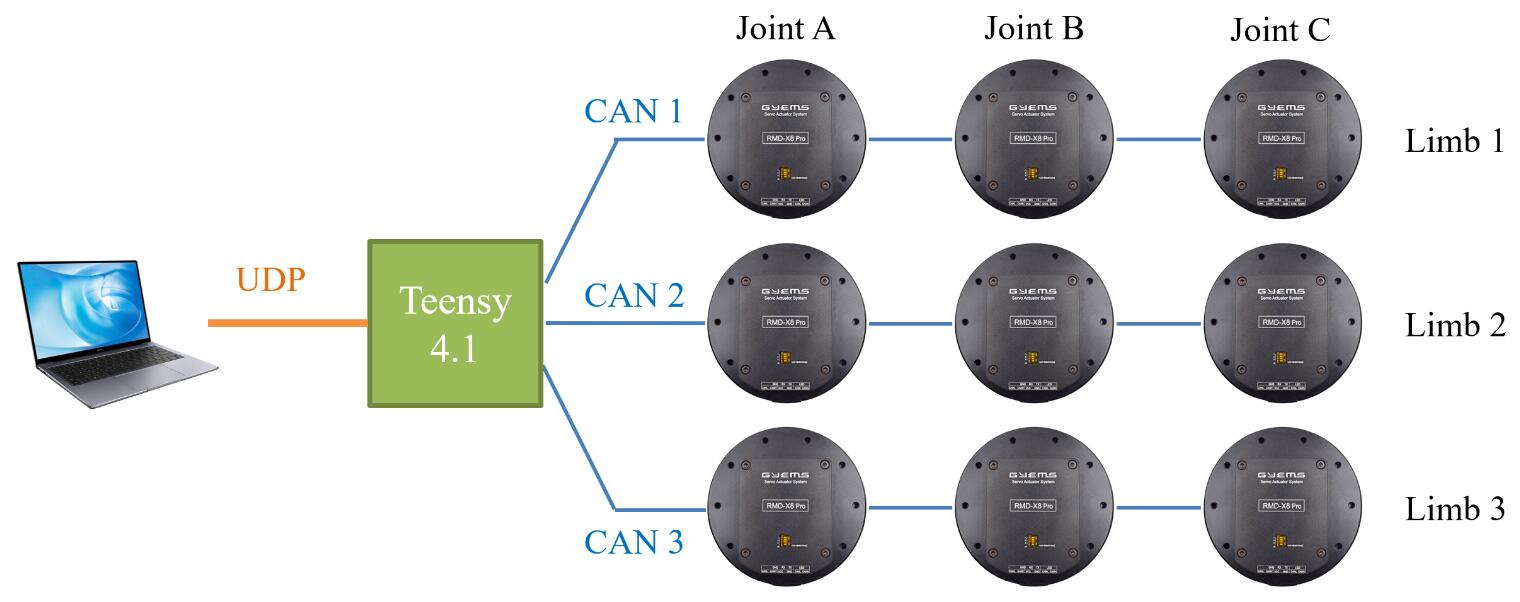

This repository functions as a hardware bridge between high-level controllers with Ethernet Ports and GYEMS-RMD motors with CAN BUS Protocol. You can directly send torque commands to up to 9 motors and receive feedback data, such as position, velocity and actual torque. In the future, other sensor data will be also intergrated here in the same way.

1_Motor_CAN: CAN BUS protocol of motors to write command and read data2_Motor_CAN_UDP: ~, UDP protocol to communicate with high-level controllers3_Motor_CAN_UDP_RTOS: ~, real-time system to schedule tasksdemo: example codes of high-level control (C/C++, MATLAB, Python)doc: figurestutorial: Arduino offical tutorials

-

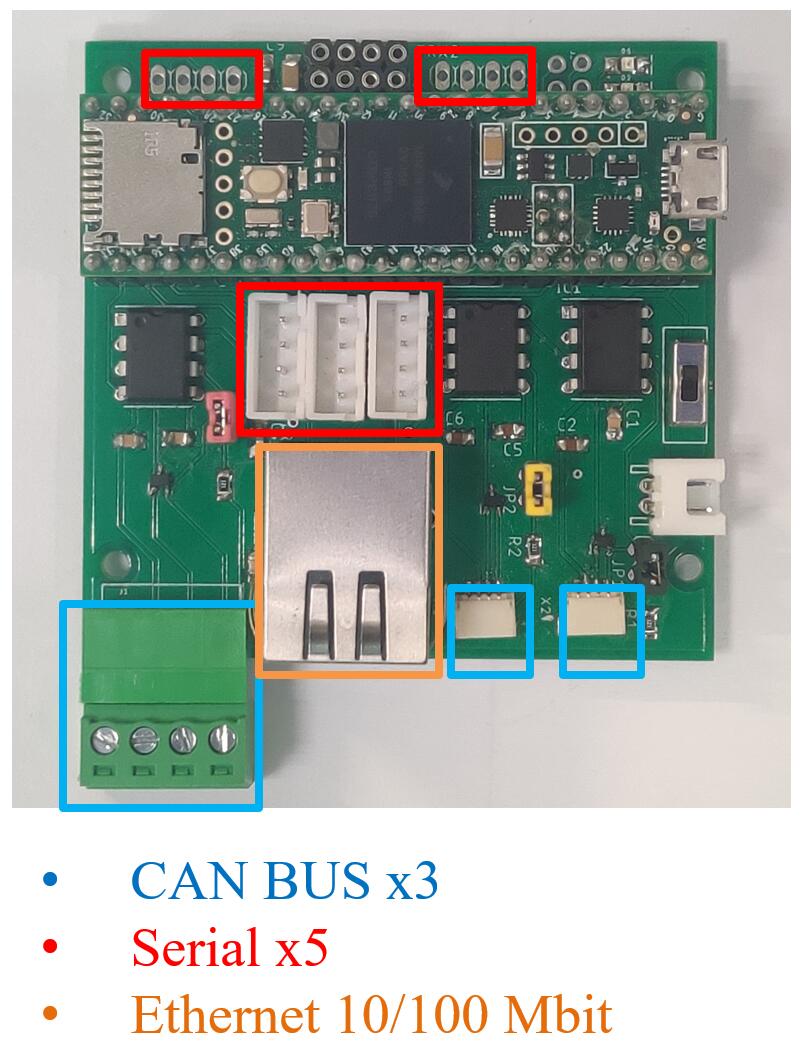

Teensy 4.1 - 600MHz, 8 serial, 3 SPI, 3 I2C, 3 CAN BUS, an Ethernet 10/100 Mbit

-

Carrier Board - Official or Self-customized

-

IDE - PlatformIO

-

IDE Setup - Teensyduino

-

CAN BUS - FlexCAN_T4

-

UDP - NativeEthernet, FNET

-

RTOS - FreeRTOS-Teensy4

Here we take a laptop with Ubuntu 18.04 as a high-level controller. In principle the code is independend of the environment, so both Windows and Linux should be OK (not yet been tested).

1) Clone this repository on your laptop. If you are using GYEMS-RMD L5015-10T motors, you can directly build the Arduino project in 3_Motor_CAN_UDP_RTOS folder and then upload to Teensy; otherwise, configure correct torque constant and reduction ratio first.

2) Connect all devices physically.

3) Configure your laptop's local IP as the following recommended settings once the wired network is indetified.

IPv4 - Manual

Address: 192.168.137.178

Netmask: 255.0.0.0

4) Compile and run the high-level example in demo/udp_c folder.

sudo gcc client.c -o client -lm

./client

For the permission error, run

cd ..

sudo chmod u+x ./udp_c -R

5) Plot test results

./plot_result.py

Delete the last incomplete line in actuator_data.txt if you meet the error IndexError: list index out of range.

You can also find Matlab version of the high-level code. However, Matlab cannot run in real time without specific hardware so be careful to use it :-)

1) Gravity Compensation

2) Position Control

3) Energy Shaping Control (Inverted Pendulum)

- From left to right: Running Actuator; Step Response; Gravity Compensation; Position Control

The code supports GYEMS-RMD motors with CAN ID 0x141, 0x142, 0x143 which means that you must configure the motor ID to 1, 2, 3 by GYEMS software RMD V2.0.exe before starting to control motors.

- The tx message

joint commandonly includes designed torque information which takes up 48 bytes.

float tau_a_des[3];

float tau_b_des[3];

float tau_c_des[3];

int32_t flags[3];

// int32_t checksum;

- And the rx message

joint datatakes up 108 bytes.

float q_a[3];

float q_b[3];

float q_c[3];

float qd_a[3];

float qd_b[3];

float qd_c[3];

float tau_a[3];

float tau_b[3];

float tau_c[3];

// int32_t flags[3];

// int32_t checksum;

So set the send buffer to TX_SIZE_32 (64 bytes) and the receive buffer to RX_SIZE_64 (128 bytes).

You can use PCAN-View to monitor CAN BUS ports.

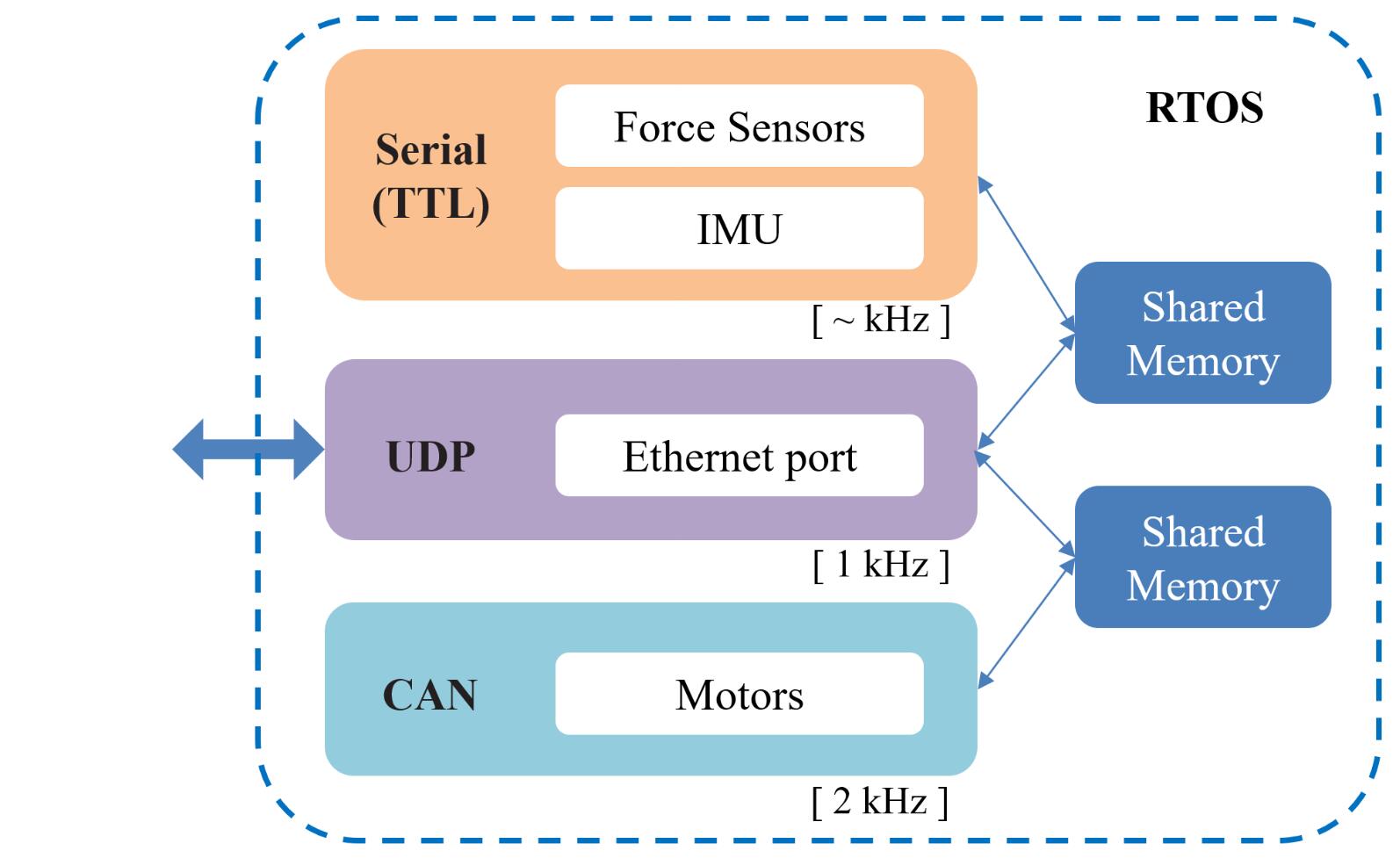

The UDP rx message includes

joint command = 48 bytes

while the UDP tx message includes

joint data = 108 bytes

force data = xx

So set the receive buffer RX_MAX_SIZE to 48 bytes while TX_MAX_SIZE is 108 bytes currently. Similarly, in high-level control code, set UDP socket buffer SO_SNDBUF = 48 bytes, SO_RCVBUF = 108 bytes.

You can use tcpdump to monitor Ethernet ports. Here the port name of my laptop is enx3c18a079c733 and the Teensy's IP and port are 192.168.137.177, 8080.

- Check the messages sent to the Teensy

sudo tcpdump -i enx3c18a079c733 -nnX 'dst host 192.168.137.177 and port 8080'

- Check the messages received by the laptop

sudo tcpdump -i enx3c18a079c733 -nnX 'src host 192.168.137.177 and port 8080'

Currently only 2 threads are scheduled.

-

UDP - priority 9; 1 kHz

-

CAN BUS - priority 8; 2 kHz

-

Bit checks in UDP and CAN BUS

-

Soft stop when an accident happens

-

Intergrating other sensors - IMU, force sensor

-

Remove or uncomment all

Serial.printorSerial.printlnfunctions since they affect threads running